The Rocker Switch

Our manufacturing facilities are located in the Bolu, Turkey, 3 hours by road from Istanbul and 2 hours from Ankara, Turkey’s capital city. We are situated under 2 hours from main ports such as Kocaeli and Zonguldak, making it convenient for sea freight as well.

Our production lines, laid across 2000 m2 of covered space, are a combination of top-notch European OEM machinery and built in-house automation modules, thanks to the process expertise developed over years by our technical team. This combination is helping us keep a low cost-base and high efficiency which we pass on to our customers.

Welcome to Best Switches of the World...

Please Visit www.boltekswitches.com for more information.

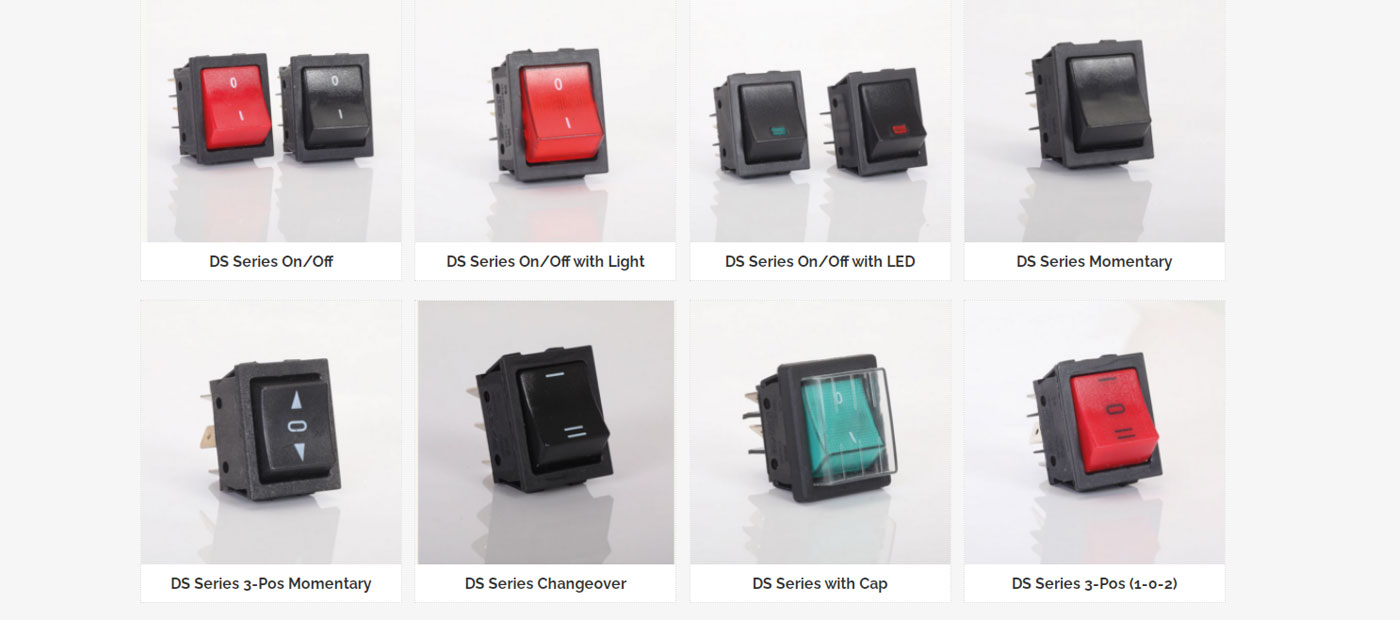

Rocker Switch Usage Areas

Rocker switches control the on / off functions of all home appliance products. The on / off function is the most important function of rocker switches, it also performs different functions such as 3 positions, button, momentary.

Switches form the actuation function that can be pressed from both ends, like a seesaw to activate or disengage the electrical circuit via the button. The longevity of the seesaw system is a very important function for a quality product. On-off life must be high in Rocker Switches.

Electrical Home Appliances

The most important place in the usage areas of rocker switches is electrical home appliances. As an example, rocker switches are used in a coffee machine or electric kettle. These switches must be resistant to heat and water for the longevity and safety of the finished product. The important point in determining the reliability of the product is the quality of the material used. While producing rocker switches, heat and fire resistant raw materials should be used. As it is used in home appliances, the safety of users is prioritized. V0 material and silver contacts used in our products are important factors that increase the quality of the product.

Another advantage of these switches is that they cannot be accidentally activated since they do not protrude. Rocker switches are much more universal and compatible with a wide variety of interior design styles. They tend to look more modern. In addition, these switches allow the user to know whether the device is turned on or off. Rocker switches can also provide illuminated feedback to the user. It can have an activated light in both open and closed positions, making the switch easy to find in the dark.

Apart from home appliances, rocker switches are used in surge protectors, display monitors, computer power supplies, printers, copiers, light systems and many other devices and applications.

For quality and safe production, product development and production area at international standards is required. Products must have various certificates of conformity. Quality controls should be carried out strictly, mass production machines suitable for the technology should be used, and a production network should be established in accordance with the standards.

Rocker Switches, which we encounter at every point of our lives, take the safety of the products we use to the highest level to keep us safe.

Technical Specifications of a Quality Switch

The most important characteristics of a quality switch are its durability and efficiency.. Durability and efficiency directly affect the quality of the end product. This increases the end user experience and the use of the end product, considering the frequency of use.

While the standard on-off life of normal switches is 10,000, our products have increased the on-off standard up to 50,000 as a result of R&D studies. This high on-off ratio in switches increases the quality of the final product and extends the life of the product, as well as decreasing the maintenance and repair cost of the product.

There are some standards in determining durability and efficiency criteria. Welded silver and brass contact components must be used in the operating system of the contacts of the Push Switches. The silver and brass pieces inside the rocker switch socket is an important component to ensure smooth current and reduce heat generation. One of the most important effects of using silver and brass is high oxidation resistance. In this way, rust does not occur with the oxidation that may occur in the sockets and does not affect the efficiency or life of the switch. For this reason, it is not easy for the product to be deformed.

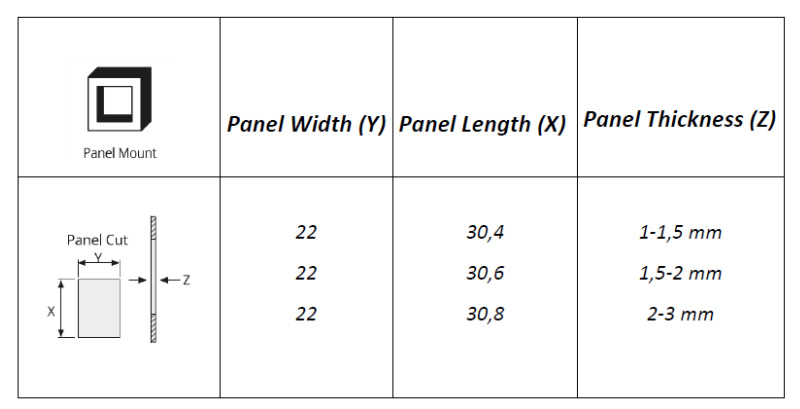

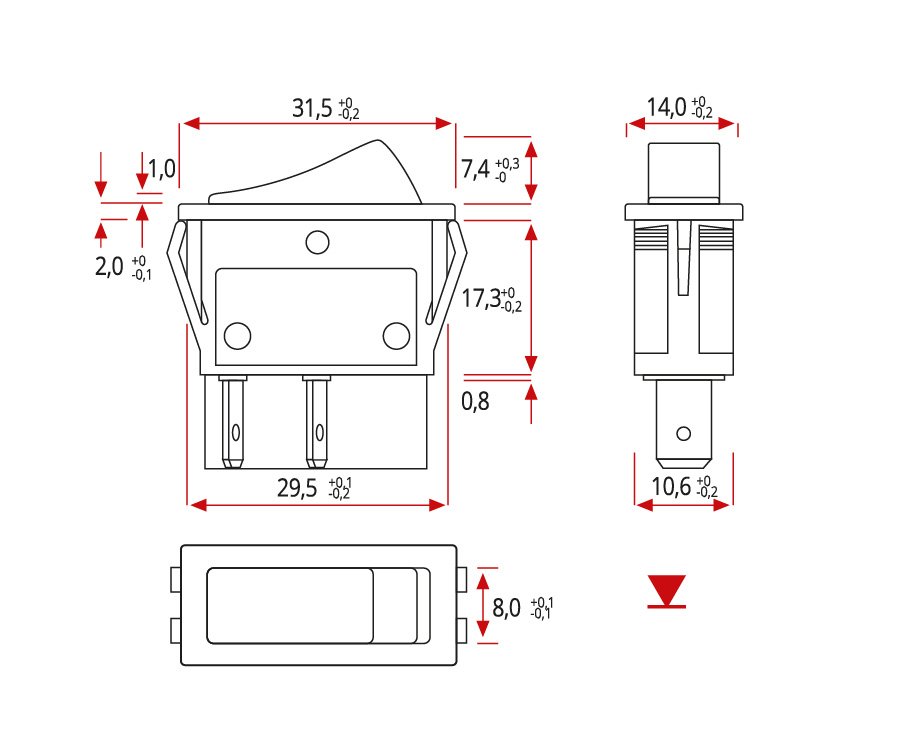

Plastic partitions used between contacts are important for safety. Product dimensions must be absolutely compatible with the panel size you will use. It must be ensured that the push switch fits exactly on the panel of the product used. Partitions used between contacts provide the advantage of easy assembly to the switch. In addition, it increases electrical safety by eliminating errors that may occur during installation. Under these safety precautions, it ensures that the final product is produced smoothly and without waste in the production line and in tests. In addition, PA 6,6, the raw material we use, adds features such as strong toughness, high mechanical strength, hardness, good fatigue resistance, higher melting point. Strong toughness; Suitable for socket parts. It is not easy to be deformed, it can maintain its function even if used for a long time. These features provide extra advantages to achieve higher efficiency. This significantly increases the product life and efficiency of Switches. Temperature resistance is 125 ° C. Electrical values of our products are 10A, 10A (2) and 16A (4).

Another issue that increases the quality of the switches is the degree of non-flammability. The material used must have a high resistance to heat. The use of high temperature resistant material expands the usage areas of the switches. The body material used for a quality switch must comply with V0 Standards.V0 standards determine the body strength of the product. In the test of these standards, an iron rod heated to 850 C is inserted into the product for 40 seconds. The determination of this temperature of 850 C has been determined in various laboratory tests to measure the durability of the product and the reaction of the switch to heat in dangerous situations to be encountered. This degree is considered to be 850 ° C in international standards. The reaction of the material used to 850 ° C is an important criterion in determining the quality of the switch.

What is a Rocker Switch?

It appears as a technical term in Electricity and Electronics. They are the Switches that we encounter in our all lives. These switches are different from the simple button we know; Switch literally means "change", that is, a button has only one function, the switch performs two tasks, turning the product on or off.

Rocker Switches house a button for operation that can be pressed on either end like a seesaw to connect or disconnect an electrical circuit. They are often used as ON/OFF switches on the main power supplies for electronic devices. The name “rocker switch” comes from the rocking motion that the switch makes when the button is pressed.

Rocker switches control the on/off functions of all home appliance products. On/off is the most important function of the rocker switch, Additionaly, it has different functions such as 3 positions, button, changeover too.

Sometimes known as a seesaw switch. The long-life of the seesaw system is a very important function for a quality product. The rocker switch consists of some main components. Let's examine these materials below.

The operation button itself clearly indicates the ON/OFF status, allowing for a visual confirmation to prevent incorrect operation.

This button is manually pressed by a person to switch between ON and OFF. Some switch has symbols printed on the button to indicate the ON/OFF status.

Sealing rubber, It prevents dust and dirt from outside. When the actuation switch is ON, this spring instantly

moves the contact to the fixed contact point and applies a high contact force

for stable contact between the two. In the OFF state, the release force of the

contact increases, which helps prevent contact welding.

Inner Case and Cover, the components that make up the switch

body (terminals, contacts and spring) are stored in the inner case and then

closed inside the cover. The cover is also designed so that the switch can be

easily mounted into a square hole in a panel.

A rocker switch can have a light activated on the face of the switch in both the on and off positions, which allows the switch to be found easily in the dark. A rocker switch may have a circle (for "on") on one end and a horizontal dash or line (for "off") on the other to let the user known if the device is on or off.

There is also a plastic compartment inside, which increases the ease of installation and electrical safety. Rocker Switches, monitors, coffee machine, kettle etc. in household products. It appears on many products, almost in every aspect of our electronic life

Rocker Switches house a button for operation that can be pressed on either end like a seesaw to connect or disconnect an electrical circuit. They are often used as ON/OFF functions on the main power supplies for electronic devices. The name “rocker” comes from the rocking motion that the switch makes when the button is pressed. Those devices control the on/off functions of all home appliance products. On/off is the most important function of a rocker switch, Additionally, it has different functions such as 3 positions, button, changeover too.Sometimes known as a seesaw switch. The long-life of the seesaw system is a very important function for a quality product. The rocker switch consis usagets of some main components. Let's examine these materials below.

On Rocker Switches, the Operation button itself clearly indicates the ON / OFF state, allowing a visual confirmation to prevent misoperation. This button is manually pressed by a person to switch between ON and OFF. Some of them has symbols printed on the button to indicate the ON/OFF status. Sealing rubber, It prevents dust and dirt from outside.

Spring, When the actuation switch is ON, this spring instantly moves the contact to the fixed contact point and applies a high contact force for stable contact between the two. In the OFF state, the release force of the contact increases, which helps prevent contact welding.

Inner Case and Cover, the components that make up the switch body (terminals, contacts and spring) are stored in the inner case and then closed inside the cover. The cover is also designed so that the switch can be easily mounted into a square hole in a panel.

A rocker switch can have a light activated on the face of the switch in both the on and off positions, which allows the switch to be found easily in the dark. A rocker switch may have a circle (for "on") on one end and a horizontal dash or line (for "off") on the other to let the user know if the device is on or off. There is also a plastic compartment inside, which increases the ease of installation and electrical safety.

Things to Consider When Purchasing a Switch

Quality observation is very important when choosing the Switch that will enter our homes and be used in many products. It will be sufficient to observe a few simple points while trying to understand its quality. Evaluating the plastics used in the product and other materials used in the content is important in quality monitoring of the product. And The importance of the Switch in determining the final quality of the product in which it is used cannot be ignored.

Let's see how to understand its quality with a few tips;

-Evaluate the plastic used. Quality Switch plastic should be made of plastic of a certain thickness, not easy to break, heat resistant and high security.

- Look at the material: Inside materials of the high-security-quality switch and socket are silver and brass. The use of high quality materials will show that the product will be long-lasting and safe. As an example, you can review our product content;

“We use high quality raw materials such as silver and brass contact terminal structure and PA 6,6

Raw Material which provides; High mechanical strength, stiffness, hardness and toughness, Good

fatigue resistance, Higher melting point etc... Temperature resistance is 125 °C. Electrical values of

our products are produced as 10A, 10A (2) and 16A (4).”

-Look for the manufacturer's logo: see if the product has any rated current, rated

voltage, power supply specification symbols, manufacturer and product number, and

safety certification. The logo of the branded product is clear.

-Request data on laboratory tests from the manufacturer. As an example, a test result for our Rocker Switch product;

“Temperature Limit T125/55:

T125°C: Ambient temperature of the rocker ''body plastic material'' working value.

T55°C: Ambient temperature of the rocker ''button plastic'' working value.

850°C Category to Heat and Fire: Glow-wire test resistance value of rocker body plastic

material (no-flame - extinction)”

-The price of the product;Producing quality at an affordable price requires automation and sectoral experience. On the basis of price alone, having to deal with the damage of a low quality product will cause great damage.

-Evaluate the total cost; Switch cost is not just its price. In case of problems with large quantities of products purchased from the Far East, there will be losses such as time and personnel costs. The cost of holding stock for a long time cannot be ignored.

-Delivery time of the switch; Switch supply time is important, Geographical proximity provides an advantage in terms of keeping up with the delivery time requested by the customer and in terms of developing new products or solving a problem.

Electrical safety is one of the most important issues in our all life. When choosing

a switch, we should not ignore that our security is at the forefront. By following

these simple steps, you can reach a high security and quality Switch that is suitable

for you.